FES for AOD (Argon oxygen decarburization Furnace)

- Primary Fume Extraction System for AOD Furnace - Argon Oxygen Decarburization Furnace or AOD for short is a type of machine for fume extraction during the melting operations where the top of the furnace vessel is equipped with a normal or a water cooled top draft suction hood to extract fumes. In order to dissipate the excess sparks or heat from the fumes, the hood additionally expands to the heat exchanger or the spark arrestor or the gas cooler. Once through this process, the fumes are collected and are cooled down, they are passed on to the bag house or the air pollution control system, or the pulse jet bag filter. This way, the dust or the fumes or the SPM gets refined and released into the atmosphere as clean air from the centrifugal and chimney. This process through the machine can control the outlet emission to as low as 2 mg/nm3 or as per the norms or guidelines of the pollution control of a given location.

- Secondary Fume Extraction system for AOD Furnace - It is quite difficult to contain all the fumes with simply just the primary fume extraction system installed in the Induction Furnace. Some fumes tend to escape during the operations of pouring, additive additions, and stop charging and form a cloud at the top of the shed. However, in the secondary fume extraction system, the problem is quite solved thanks to the many hoods installed at the top of the shed with the automatic dampers throughout. These dampers have the capacity to sense the fumes and automatically open and extract from the shed top the fumes to transport it to the bag filter or air pollution control system or pulse jet bag filter. The dampers can also be opened manually as required to form a furnace platform. After the gases and fumes are filtered, it is released in the atmosphere via ID Fan and chimney leaving the outlet emission to about as low as 2 mg/nm3 as per the guideline of pollution control for a certain location.

- Dog House Fume System for AOD Furnace - Dog House Fume Extraction is an independent and unique way of fume extraction through which the need for the use of a secondary furnace fume extraction system is eliminated and the process can be finished independently via the Dog House Fume System. This apparatus has a large sized hood for travelling through which, all the fumes are collected at the stage of operation like Additives, Pouring, and charging. Via this method, there is a compulsion to the process, i.e the scrap charging must be done through the travelling vibro-feeder and the collection of molten metal by tapping to the ladle. Furthermore, upon completion of the extraction process, the next step is the same as the primary step. This method enables the outlet emission to be controlled up to as low as 2 mg/nm3. The level shall depend on the pollution control norms of the particular given area.

|

FES for EAF (Electric Arc Furnace)

- The Electric Arc Furnace (EAF) extracts the fumes generated within through a 4th hole on the top cover of the apparatus. It is a relatively completed closed furnace, the apparatus needs to be water cooled through the ducts as the internal temperature runs very hot. Upon the extraction of the fumes, they travel through different stages, namely, the gas cooler or heat exchanger to cool down the temperature followed by the pulse jet bag filter or bag house to filter the fumes. After the filtration is set and complete, the next process comprises of the fumes to pass through the ID fan and the chimney before being released into the atmosphere. The EAF can control the outlet emission in the atmosphere by as low as 2 mg/nm3 depending on the pollution control norms of that particular location. One thing about the EAF is that it requires the combination of both the primary and secondary FES since the extraction of the dog house type is not quite possible through this furnace.

|

FES for LRF (Ladle Refining Furnaces)

- The Ladle Refining Furnaces are primarily operated in order to calibrate the properties of the molten metal or hike the molten metal’s temperature. The furnace usually consists of a pulse jet bag filter, centrifugal fan or blower, and a suction hood. The furnace can contain the relatively low emission of fumes generated in the process through a central secondary fume extraction system positioned at the top of the shed.

|

FES for Induction Furnaces

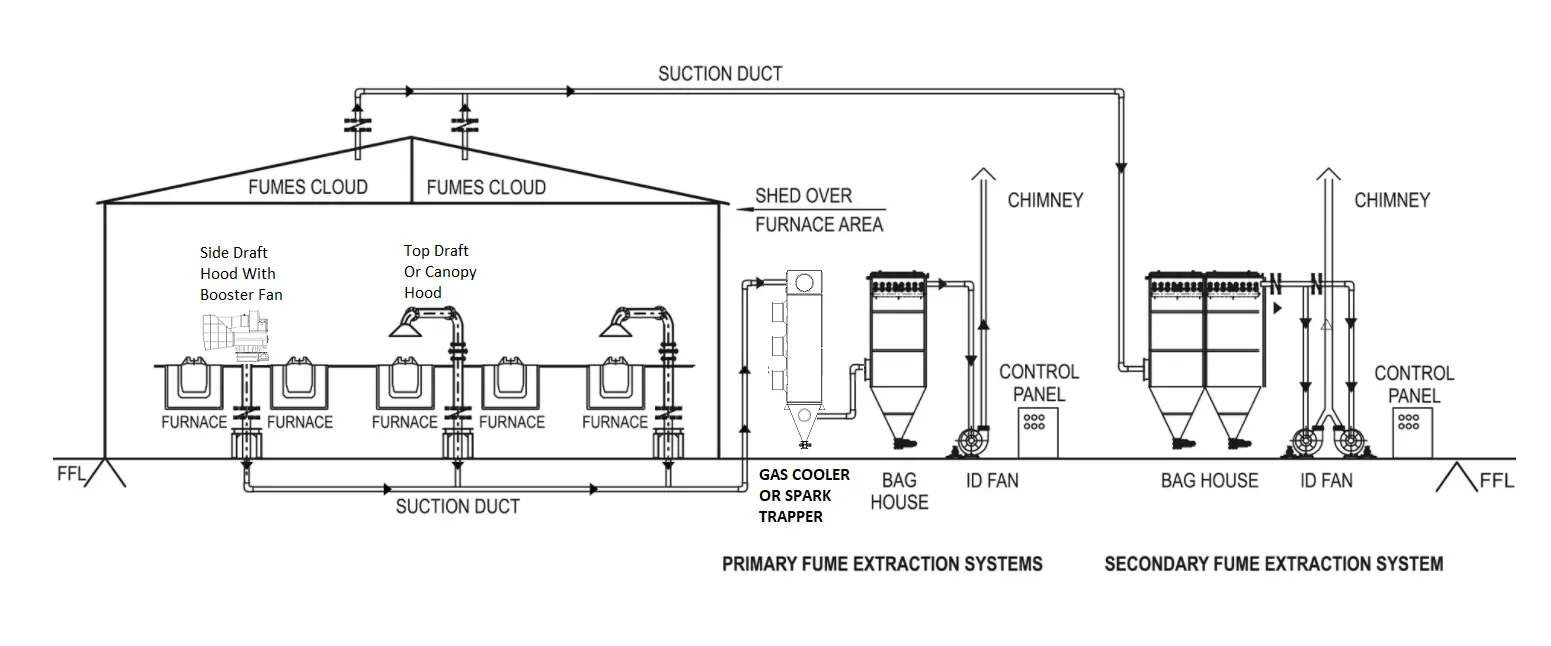

- Primary Fume Extraction System for Induction Furnace - Induction furnaces are a popular choice globally amongst different different furnace systems. At the top or side of these systems to draw out and purify the fumes during melting, they are equipped with a side draft or top draft suction hood. To get rid of the excess spark or heat from the fumes, the hood extends further to the spark arrestor or the heat exchanger or the gas cooler. Once these fumes cool off, they pass through the Air Pollution Control System or the bag house. There the dust or fumes or the SPM gets purified. Followed by this, the clean air travels through the final two steps, passing through the centrifugal fan and then via the chimney or stack into the atmosphere. The outlet emission thanks to the machine can be as low as 2 mg/nm3. The figure depends on the requirement per a particular location’s norms for the pollution control.

- Secondary Fume Extraction system for AOD Furnace - It is quite difficult to contain all the fumes with simply just the primary fume extraction system installed in the Induction Furnace. Some fumes tend to escape during the operations of pouring, additive additions, and stop charging and form a cloud at the top of the shed. However, in the secondary fume extraction system, the problem is quite solved thanks to the many hoods installed at the top of the shed with the automatic dampers throughout. These dampers have the capacity to sense the fumes and automatically open and extract from the shed top the fumes to transport it to the bag filter or air pollution control system or pulse jet bag filter. The dampers can also be opened manually as required to form a furnace platform. After the gases and fumes are filtered, it is released in the atmosphere via ID Fan and chimney leaving the outlet emission to about as low as 2 mg/nm3 as per the guideline of pollution control for a certain location.

- Dog House Fume System for AOD Furnace - Dog House Fume Extraction is an independent and unique way of fume extraction through which the need for the use of a secondary furnace fume extraction system is eliminated and the process can be finished independently via the Dog House Fume System. This apparatus has a large sized hood for travelling through which, all the fumes are collected at the stage of operation like Additives, Pouring, and charging. Via this method, there is a compulsion to the process, i.e the scrap charging must be done through the travelling vibro-feeder and the collection of molten metal by tapping to the ladle. Furthermore, upon completion of the extraction process, the next step is the same as the primary step. This method enables the outlet emission to be controlled up to as low as 2 mg/nm3. The level shall depend on the pollution control norms of the particular given area.

|

FES for Zinc Furnaces

- Zinc Furnaces, the furnaces that are mostly fired by gas or induction, are used to extract the fumes exuded. The extracted fumes are used as a product for the melter. Zinc powder is apprehended using this fume extraction system through the bag filter discharge and packed directly. The machine can bring down the outlet emission level by as low as 2 mg/nm3.

|

FES for TRF (Tilting rotary furnace) & Skelner furnaces

- The Skelner Furnace and Tilting Rotary Furnace is generally used in the aluminium smelting plants and in aluminium recycling. These systems usually have a wet scrubber, pulse jet bag and a suction hood. Depending on the pollution control norms of the given particular location and upon installation, these machineries can help control the outlet emission to up to as low as 2 mg/nm3.

|

FES for Exothermic Reaction Furnace

- Since there are always multiple exothermic reaction furnaces installed, the Furnace Fume Extraction Systems are installed in order to accumulate the fumes that these exothermic reactions cough out. These systems usually come equipped with a gas cooler, pulse jet bag filter, suction hood, and centrifugal fan. These machines have the capacity to control the emissions and bring them down to about as low as 2 mg/nm3 based on a particular geographic area’s pollution control norms.

|

CNC Plasma and Laser Cutting

- In order to apprehend and filter the generated fumes from any cutting operations, Plasma cutting or Fumer Extraction Systems for CNC Lasers are used. Such systems generally consist of a pulse jet cartridge, suction and cutting table, and pulse jet dust collector of centrifugal blower.

|

Welding Fume Extraction

Welding Operations like MIG, TIG, Brazing, Soldering, and SMAW generates fumes. TECHFLOW provides the practical, ideal, and the finest solutions for the fume extraction like:-

- For multiple stations of SMAW welding, we have the central welding fume extraction system. The system has various suction arms for ducting, centrifugal fan or blower with automation of dampers and blower, welding fumes, pulse jet cartridge filter or pule jet dust collector.

- Another one of our fume extraction solutions is the Mobile Welding Fume Extraction Unit. This machine acts as a stand alone unit with many great accessories like Filter Cartridge & Centrifugal Blower, Wheels to transport it anywhere, a flexible 360 Deg Rotating arm, and more.

|

Centrifugal fans and blowers for steel plant

We, at Techflow, make and supply some of the best and most trusted industrial grade centrifugal blowers and fans with wide applications like :–

- ABC Fans

- ID Fan for ESP

- Kiln Fans

- Nose Cooling Fans

- Other Processing Fans and blower

- ID fan

|

Air Pollution Control System / Bag Filter for Various Application of DRI Plant, Captive Power Plant, Crusher Houses, Steel Plant / Dust Collection Systems

TECHFLOW is a trustworthy and coveted manufacturer supplier of Mineral Grinding to Control the dust particles, de-dusting system, Stone Crushing, Dust Extraction Systems, pulse jet bag filters for DRI like crushing plants.

- Silo Venting

- Hopper Discharge

- Belt to Bin Transfer

- Jaw Crushers

- Vibro Screens

- 5.Belt Transfer

|